While manufacturing air cooled chiller creators pay considerable attention to the fans. They are produced by almost the most extensive energy consumers after the compressor and probably the pump. Let us consider different types of fans.

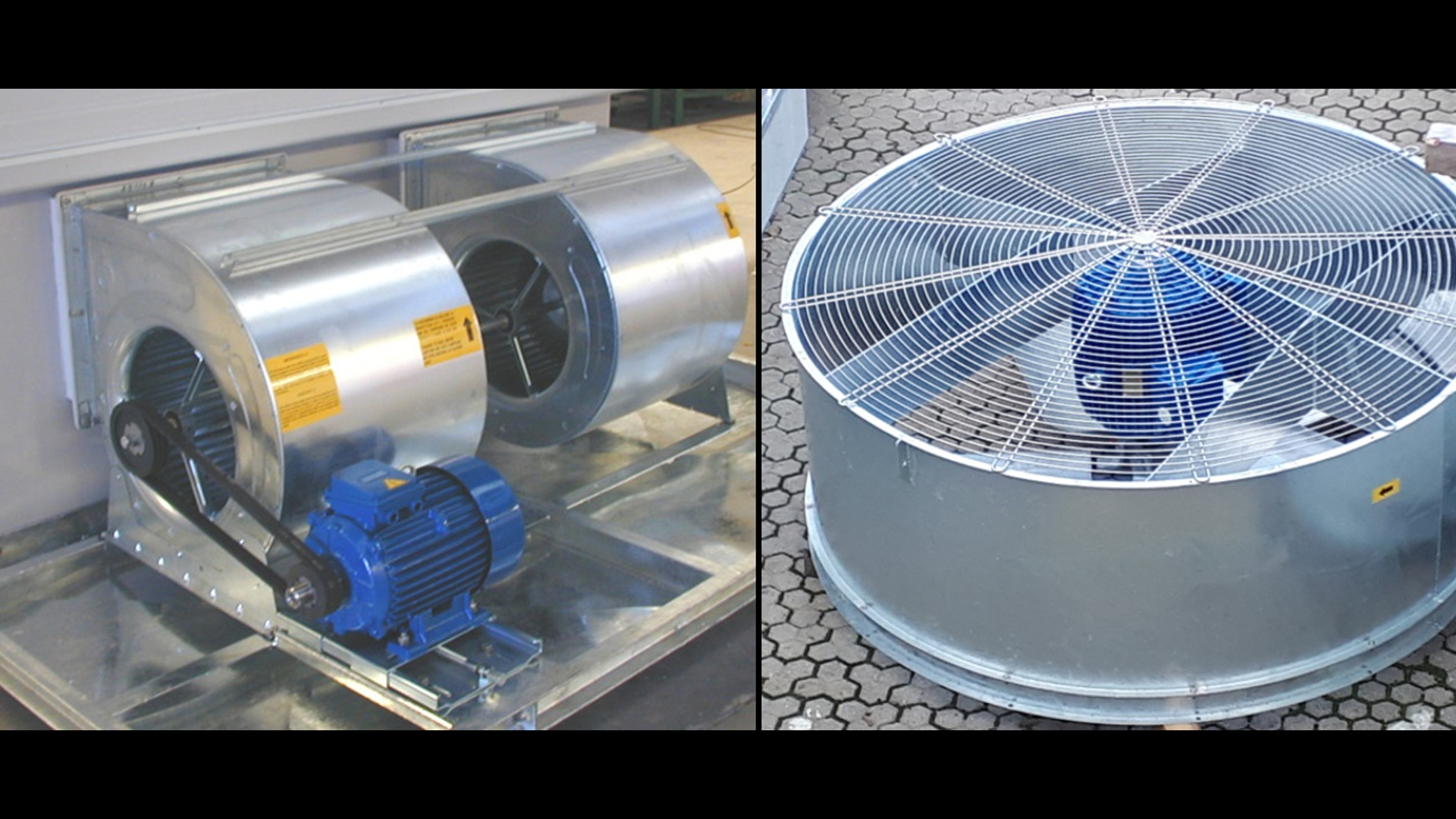

Chillers with Axial Fans

The cooling process of the condensers takes place by means of airflow from the environment. The main advantage of using such equipment is the unique possibility of using unused areas for the introduction of air conditioning systems. Its main disadvantage is noise, which is inevitably an accompanying component during the operation of mechanisms.

To minimize or eliminate this drawback, manufacturers use special fans that are equipped with a low noise level and have specially shaped blades. It is worth noting that quite often this leads to an increase in certain dimensions of the structure. That is why the consumer can be offered such an alternative as a reduced noise level or small dimensions. Quite often, a chiller with a remote condenser is produced when it is located outdoors, and the refrigeration module itself is indoors.

Chillers with Centrifugal Fans

A chiller equipped with a centrifugal fan must be installed inside buildings. Both the supply of cooling air and the removal of heat are due to the air duct system. In turn, centrifugal fans, which are characterized by an impressive static set. It makes it possible to overcome air duct resistance, and is able to move air.

An important advantage of this type of equipment is all the seasonality of the work performed. It can be used under various weather conditions, as well as ambient temperatures. In order to avoid a shortage of installations for the units, a special area of the overall size inside the structure must be allocated. In addition, ancillary costs will be required to create a mandatory duct network.